How Often Does The Air Handler Need Maintenance Service?

Regular maintenance of an air handler is crucial to ensure optimal performance and energy efficiency and prolong its lifespan. The frequency of maintenance may vary depending on factors such as usage, environment, and manufacturer recommendations.

Air Cleaning Technologies offers air handler maintenance service in Loudoun County, Fairfax County, Manassas, VA, Leesburg, Frederick, MD, Annapolis, and surrounding areas.

These are some things to consider:

- Manufacturer Recommendations: It’s essential to adhere to the manufacturer’s guidelines regarding maintenance intervals. Typically, manufacturers provide specific recommendations regarding the frequency of maintenance tasks such as filter changes, lubrication of moving parts, and inspection of electrical components. Following these guidelines helps ensure that the air handler operates efficiently and reduces the risk of unexpected breakdowns.

- Seasonal Inspections: Conducting maintenance on the air handler at least twice a year, preferably before the start of the cooling and heating seasons, is advisable. Before the summer months, inspecting and servicing the air handler can help address any issues that may have arisen during the winter months of inactivity, such as dust accumulation or minor mechanical issues. Similarly, preparing the unit before the onset of winter ensures it operates efficiently during the colder months.

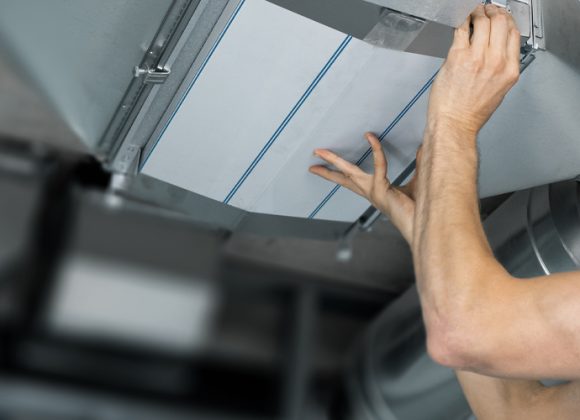

- Filter Replacement: Regularly changing the air filters is one of the most critical maintenance tasks for an air handler. Clogged or dirty filters restrict airflow, reducing the system’s efficiency and potentially leading to strain on the equipment. Depending on the type of filter and usage, filters should typically be replaced every one to three months. However, in environments with higher levels of dust or allergens, more frequent replacement may be necessary.

- Cleaning Coils and Drain Lines: Over time, the evaporator and condenser coils of the air handler can accumulate dirt, dust, and debris, hindering heat transfer and reducing efficiency. Cleaning these coils periodically, along with inspecting and clearing the condensate drain lines, helps prevent issues such as mold growth and water damage.

- Inspecting Belts and Bearings: Belts and bearings in the air handler’s motor and blower assembly should be inspected regularly for signs of wear and tear. Worn-out belts can lead to slippage and reduced airflow, while faulty bearings may cause excessive noise or motor failure. Lubricating moving parts as needed can help prevent premature wear and ensure smooth operation.

- Checking Electrical Components: Regularly inspecting electrical connections, controls, and safety switches is vital for identifying any potential issues such as loose connections or corrosion. Addressing these issues promptly can prevent electrical failures and ensure the safe operation of the air handler.

By adhering to a regular maintenance schedule and addressing any issues promptly, homeowners or facility managers can ensure their air handler operates efficiently and reliably throughout its lifespan.

Should you have any questions, feel free to give us a call.